The journey of Diecasting Solutions started in the back of a North Shore factory in early 2004, when an absence of players in the Australasian die-casting industry inspired David Dale (Director) to set out and convert a plastic molding machine into a Zinc die-casting machine.

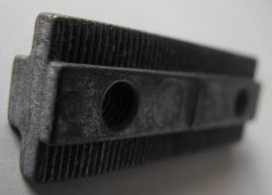

Today, their unique die-casting machines prove for faster delivery, allowing them to run up to five dies in each machine at a time and change dies in less than ten minutes, whilst maintaining high quality cast parts.

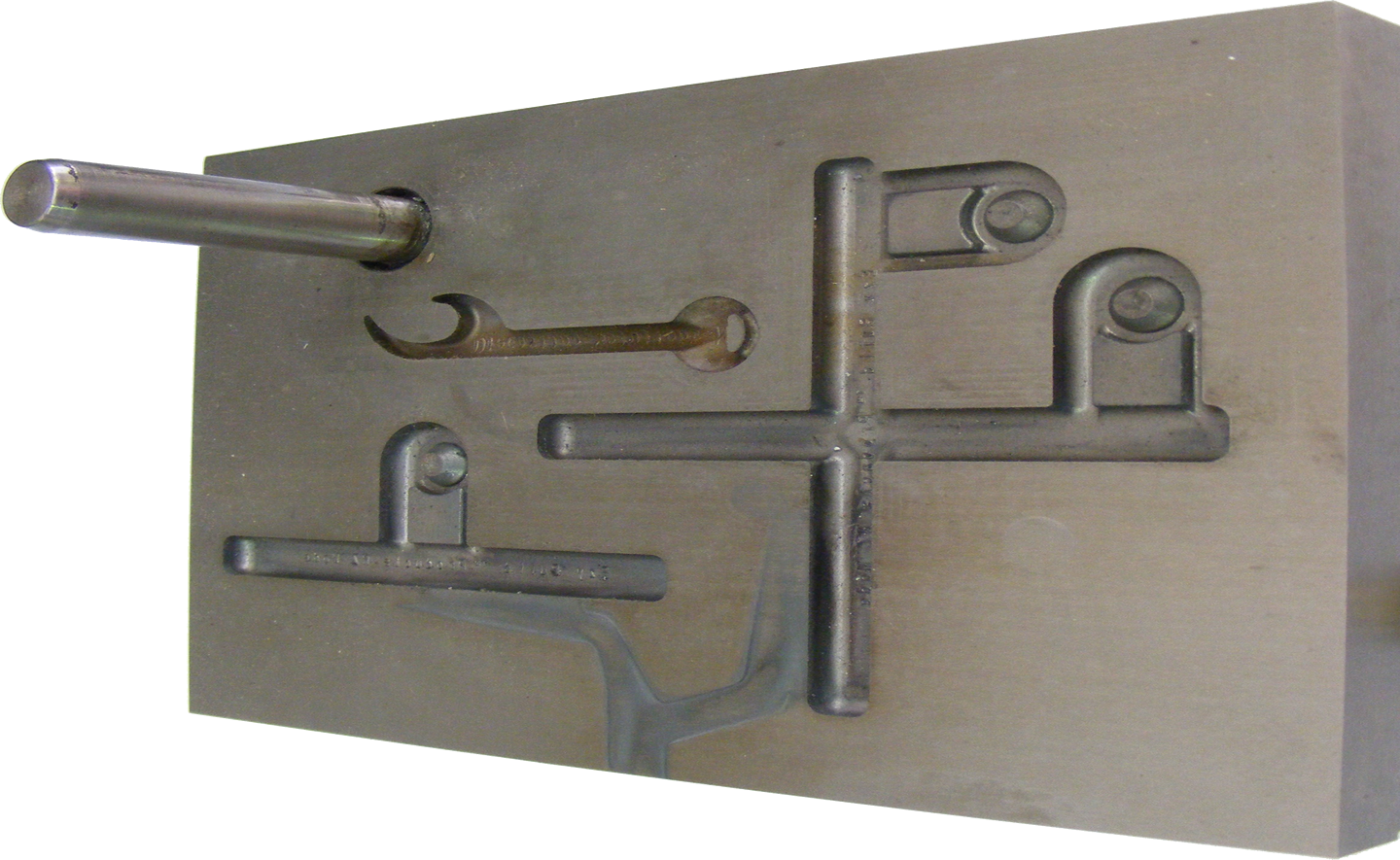

Incorporating both his design and tool-making background, David brought these services in-house, bridging the gap between client, designer and toolmaker. This highly effective scenario reduces costs associated with outsourcing tool-making and cuts production time.

This one stop shop has worked well for Diecasting Solutions, designing and manufacturing hundreds of products for clients in Europe, Australia and New Zealand.

Contact us today to discuss your requirements.